The GM trucks from 2014 on are no Direct Injection and the intake valve coking issue now affects the V8's (where until now the ecotech 4L and the 3.6L V6's have been the biggest problem engines).

Stopping the oil ingestion into the intake charge is now more important than ever.

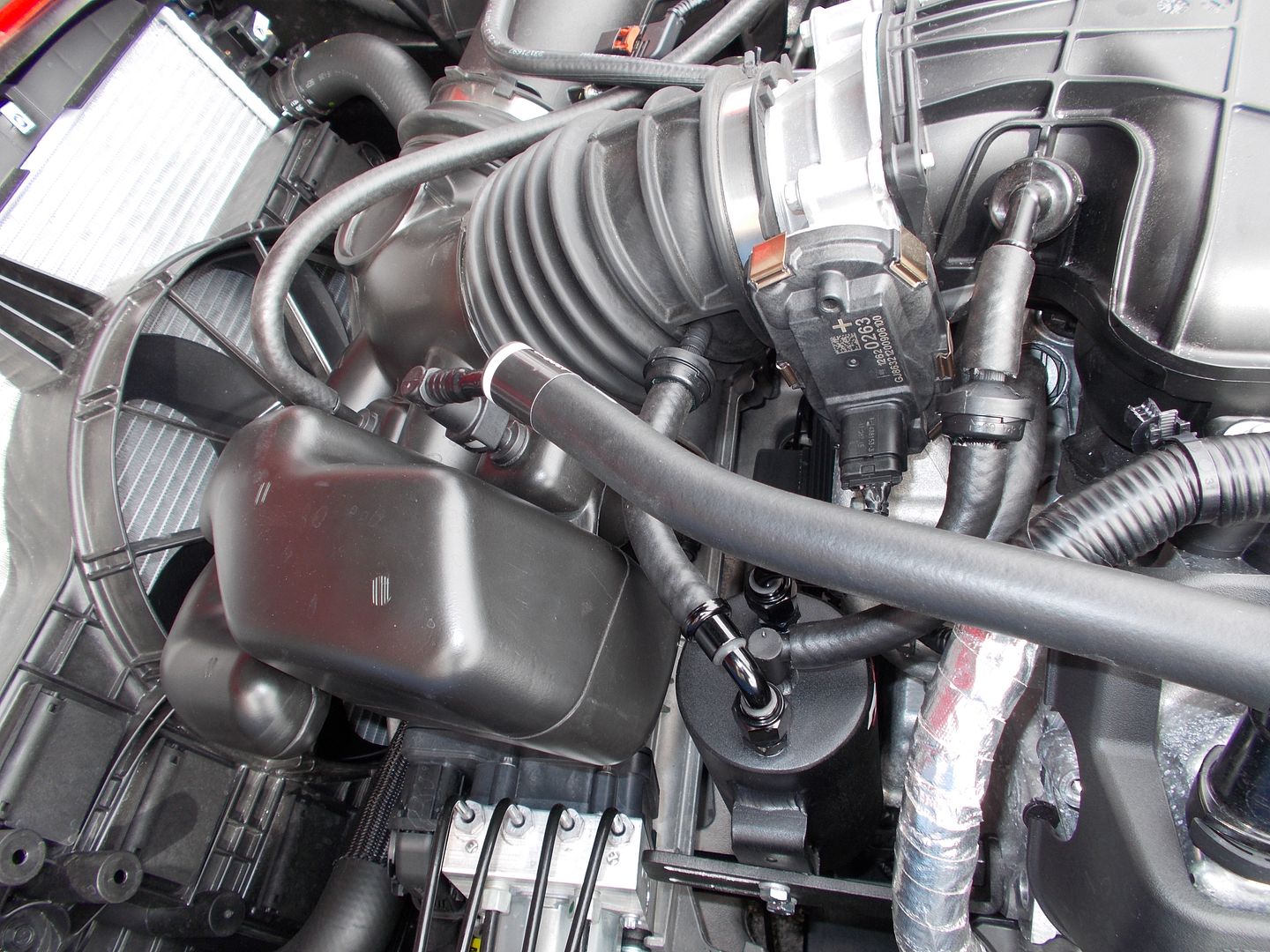

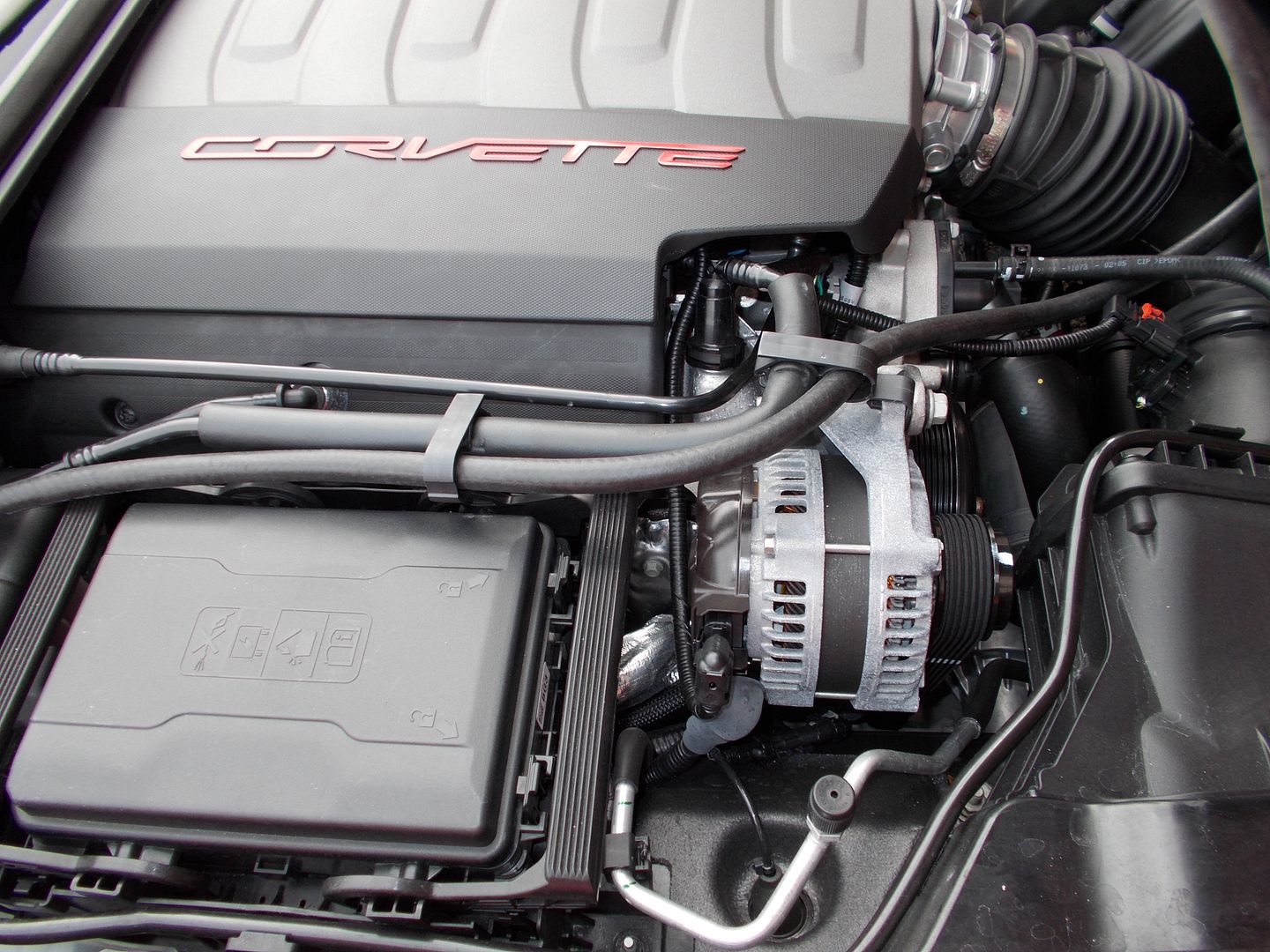

This issue is covered here for the new Corvette, but the Truck 6.2 is configured the same except for the dry-sup.

Let me know any that have questions. Easier to stop this from happening from the beginning VS after the deposits have formed:

The detonation and carbon deposits most probably already know about, so we will focus on the brand new issue of Direct injection.

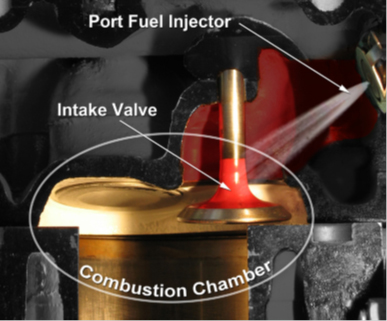

Most can remember seeing the placards on a Shell/Mobil/Chevron fuel pump with the dirty and clean intake valves, well these are accurate and not just marketing. In the past, the detergent additives of the top tier fuels kept deposits from forming on intake valves as with the port injection engines the injectors kept a constant spray of fuel showering the valves so we never had to wory aoubt intake valve coking:

![Image]()

Direct injection has a ton of technical improvements over port injection such as allowing greater power to made from a higher compression ratio (11.5:1 vs 10.2:1 port injection) as the fuel is only introduced into the combustion chamber during the final 20-30% of the compression stroke, we no longer have as high of a probability of detonation (pre-ignition) from a hot spot like carbed or port injection. Also, since the pressure the fuel is delivered to the injector is 2,000-3,000 PSI atomization is far better and now fuel injectors never have a chance to build up deposits. This also results in better fuel economy, and more.

The one downside the industry did not anticipate is now since the fuel never touches the intake valves, the oil present in the PCV vapors bakes on to, or "Cokes" the intake valves resulting in a degradation in power and MPG in as little as 10-15k miles since no fuel ever touches the intake valves:

![Image]()

This results in buildup on the intake valves as shown here:

![Image]()

This is NOT a GM only issue, it affects every make/model of DI 4 stroke engine including motorcycles, outboards, and snowmobiles. Some more than others as you can see in this link of photos from techs all over the world:

https://www.google.com/search?q=intake+ ... 6&dpr=0.95

GM has made great strides in the much improved baffles in both the valve covers and the valley cover where the crankcase dirty side is evacuated through, but there is still a ton of oil entering the intake air charge from 2 points.

One is the dirty side (foul) that is common in the past, the valley cover so a good catchcan will stop that, but the other is the same as the earlier C6 Z06 dry sump tank vent that burps oil into the intake air bridge before on the c6, and now into the baffles on the OEM air box with the C7.

![Image]()

Many may have seen the pictures Ron at Vengence posted elsewhere of the bag full of oil they found on the fiorst C7 in, and here is what we found on this brand new one (after the first 3 from Ron):

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Here is a step by step pictorial of what we see, and how it is cured:

First, we are using the dual valve can with integrated flow controlling checkvalves mounted inline and the RX cleanside separator at the oil sump:

![Image]()

Lets look at where the oil ingests, and how the C7 engine 's PCV system works.

First, the filtered, MAF measured fresh air enters the drivers side valve cover via this main line from the airbox baffles:

![Image]()

Since this we will be correcting with a secondary suction/evac source preventing reversion, or back flow through this into the air box, we are leaving this line intact.

Then the passenger side valve cover has two fittings that join and vent through the drysump tank and also connect to the airbox. Then a line runs from the tank to the airbox. This is the problem one as it allows a path for any oil from the tank to "burp" directly into the airbox. So this is removed (note it has insulation on it):

![Image]()

![Image]()

We then replace the oil fill cap on the sump tank with the RX cleanside oil separator, and connect the enclosed line from the separator to the air box barb left open from removing the OEM line:

![Image]()

This now will trap the oil that does "burp" and hold it in the separator during the moments when the oil would exit (during hard cornering, braking, acceleration) and holds it from ingestion until the flow pulls it back in when in full vacuum mode (idle, deceleration, or cruising). So now we have the clean, or fresh side addressed, lets get to the real culprit of steady oil ingestion. This is the U shaped convoluted line that runs from the Intake manifold vacuum barb down to the valley cover barb just below. This is all new for 2014 and has a much improved baffle under the valley cover in an attempt to slow oil ingestion, and the exit barb it'self is now a one-way checkvalve VS the restrictive fixed orifice of the L99 and LS3 versions (that were too restrictive to allow proper evacuation). So props to GM for addressing part of this issue (we have used the checkvalves for 12 years now back with the C5 to correct this issue). So this helps reduce the backflow, or reversion during WOT, but does not eliminate it, and we will get to how we correct that as well.

So here is the foul side line (Note the vacuum barb now is on the drivers side of the IM snout VS the passenger side on the gen 3 &4 versions of the LS engine):

![Image]()

![Image]()

![Image]()

![Image]()

And the one way checkvalve valley cover barb where all the crankcase vapors along with the oil most and damaging combustion byproducts are evacuated:

![Image]()

By simply pressing the tabs, these lines will quick disconnect, and the barbs are 3/8" so the included lines with the RX system slide snugly on all.

Now we simply connect the center of the RX can to the valley barb (and since it already is a checkvalve, no additional valve need be installed here):

![Image]()

And the primary outlet of the RX can will now connect to the vacuum barb left open after removing the U shaped OEM tube, WITH a checkvalve flowing away from the can (this is to ensure no mixing and reversion)

And finally, the secondary outlet with checkvalve flowing away from the can will run to a hole drilled into the coupler just in from of the throttle body. This is going to provide suction for evacuation while in WOT operating mode when vacuum inside the IM is non existent from he reversion pulses present. This will now ensure the flow is always traveling in the right direction, and the checkvalve prevents any backflow.

The RX can will separate the oil and other compounds from the vapors and only cleansed vapors are entering the intake air charge preventing the intake valve coking as well as the other oil caused issues most are aware of.

Here is the entire system.

as it is finished:

![Image]()

![Image]()

![Image]()

Any questions, just ask.

Stopping the oil ingestion into the intake charge is now more important than ever.

This issue is covered here for the new Corvette, but the Truck 6.2 is configured the same except for the dry-sup.

Let me know any that have questions. Easier to stop this from happening from the beginning VS after the deposits have formed:

The detonation and carbon deposits most probably already know about, so we will focus on the brand new issue of Direct injection.

Most can remember seeing the placards on a Shell/Mobil/Chevron fuel pump with the dirty and clean intake valves, well these are accurate and not just marketing. In the past, the detergent additives of the top tier fuels kept deposits from forming on intake valves as with the port injection engines the injectors kept a constant spray of fuel showering the valves so we never had to wory aoubt intake valve coking:

Direct injection has a ton of technical improvements over port injection such as allowing greater power to made from a higher compression ratio (11.5:1 vs 10.2:1 port injection) as the fuel is only introduced into the combustion chamber during the final 20-30% of the compression stroke, we no longer have as high of a probability of detonation (pre-ignition) from a hot spot like carbed or port injection. Also, since the pressure the fuel is delivered to the injector is 2,000-3,000 PSI atomization is far better and now fuel injectors never have a chance to build up deposits. This also results in better fuel economy, and more.

The one downside the industry did not anticipate is now since the fuel never touches the intake valves, the oil present in the PCV vapors bakes on to, or "Cokes" the intake valves resulting in a degradation in power and MPG in as little as 10-15k miles since no fuel ever touches the intake valves:

This results in buildup on the intake valves as shown here:

This is NOT a GM only issue, it affects every make/model of DI 4 stroke engine including motorcycles, outboards, and snowmobiles. Some more than others as you can see in this link of photos from techs all over the world:

https://www.google.com/search?q=intake+ ... 6&dpr=0.95

GM has made great strides in the much improved baffles in both the valve covers and the valley cover where the crankcase dirty side is evacuated through, but there is still a ton of oil entering the intake air charge from 2 points.

One is the dirty side (foul) that is common in the past, the valley cover so a good catchcan will stop that, but the other is the same as the earlier C6 Z06 dry sump tank vent that burps oil into the intake air bridge before on the c6, and now into the baffles on the OEM air box with the C7.

Many may have seen the pictures Ron at Vengence posted elsewhere of the bag full of oil they found on the fiorst C7 in, and here is what we found on this brand new one (after the first 3 from Ron):

Here is a step by step pictorial of what we see, and how it is cured:

First, we are using the dual valve can with integrated flow controlling checkvalves mounted inline and the RX cleanside separator at the oil sump:

Lets look at where the oil ingests, and how the C7 engine 's PCV system works.

First, the filtered, MAF measured fresh air enters the drivers side valve cover via this main line from the airbox baffles:

Since this we will be correcting with a secondary suction/evac source preventing reversion, or back flow through this into the air box, we are leaving this line intact.

Then the passenger side valve cover has two fittings that join and vent through the drysump tank and also connect to the airbox. Then a line runs from the tank to the airbox. This is the problem one as it allows a path for any oil from the tank to "burp" directly into the airbox. So this is removed (note it has insulation on it):

We then replace the oil fill cap on the sump tank with the RX cleanside oil separator, and connect the enclosed line from the separator to the air box barb left open from removing the OEM line:

This now will trap the oil that does "burp" and hold it in the separator during the moments when the oil would exit (during hard cornering, braking, acceleration) and holds it from ingestion until the flow pulls it back in when in full vacuum mode (idle, deceleration, or cruising). So now we have the clean, or fresh side addressed, lets get to the real culprit of steady oil ingestion. This is the U shaped convoluted line that runs from the Intake manifold vacuum barb down to the valley cover barb just below. This is all new for 2014 and has a much improved baffle under the valley cover in an attempt to slow oil ingestion, and the exit barb it'self is now a one-way checkvalve VS the restrictive fixed orifice of the L99 and LS3 versions (that were too restrictive to allow proper evacuation). So props to GM for addressing part of this issue (we have used the checkvalves for 12 years now back with the C5 to correct this issue). So this helps reduce the backflow, or reversion during WOT, but does not eliminate it, and we will get to how we correct that as well.

So here is the foul side line (Note the vacuum barb now is on the drivers side of the IM snout VS the passenger side on the gen 3 &4 versions of the LS engine):

And the one way checkvalve valley cover barb where all the crankcase vapors along with the oil most and damaging combustion byproducts are evacuated:

By simply pressing the tabs, these lines will quick disconnect, and the barbs are 3/8" so the included lines with the RX system slide snugly on all.

Now we simply connect the center of the RX can to the valley barb (and since it already is a checkvalve, no additional valve need be installed here):

And the primary outlet of the RX can will now connect to the vacuum barb left open after removing the U shaped OEM tube, WITH a checkvalve flowing away from the can (this is to ensure no mixing and reversion)

And finally, the secondary outlet with checkvalve flowing away from the can will run to a hole drilled into the coupler just in from of the throttle body. This is going to provide suction for evacuation while in WOT operating mode when vacuum inside the IM is non existent from he reversion pulses present. This will now ensure the flow is always traveling in the right direction, and the checkvalve prevents any backflow.

The RX can will separate the oil and other compounds from the vapors and only cleansed vapors are entering the intake air charge preventing the intake valve coking as well as the other oil caused issues most are aware of.

Here is the entire system.

as it is finished:

Any questions, just ask.