Good Morning All,

New to the forum because I've been trying to troubleshoot an A/C problem in my 2002 Silverado 1500 for some time and it's got me flummoxed.

Starting just this season, I've noticed the air coming from the vents when the A/C was on was only slightly cooler than outside temperature. The A/C was doing something - but not much. Borrowed a set of manifold gauges from the local Auto Plarts place and took a look on a few different days - most recently yesterday - and here's the situation:

Weather website said the outside temp was 77 degrees with 39% humidity. I start the car, let the A/C run for a while, then revved it to 2000 RPM for about a minute and let things settle back down. Ended up with a high-side pressure of about 160psi, low-side pressure just about 26psi, compressor running pretty steadily and not cycling fast like when initially running. Low-pressure side of the line running into the evaporator core through the firewall was cold, but not ice cold and return line coming out of the evap core much warmer. However, I stuck a thermometer in the vent and the air temp was only around 72 degrees - just barely below ambient.

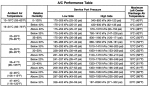

I replaced the cabin air filters to make sure I was getting sufficient air flow over the evaporator core, but that had no real effect. I have a digital copy of the factory service manual and walked through much of the troubleshooting although it heavily leans on specifics of the automated testing tools they've got in the service centers. The acceptable pressures are given in this table, however, and this leads me to beleive that the compressor and controls are working as they should be:

![AC Performance Table.png AC Performance Table.png]()

So I guess my question is this: Where do I look next? I'm not an A/C expert and I'm desperately hoping it's not a bad evaporator core because I don't want to disassemble the whole car interior. It's pretty cheap and easy to replace the accumulator, orifice tube, and even condenser, but I don't want to just throw parts at it if there's some other troubleshooting I could do. Thanks in advance for any help.

New to the forum because I've been trying to troubleshoot an A/C problem in my 2002 Silverado 1500 for some time and it's got me flummoxed.

Starting just this season, I've noticed the air coming from the vents when the A/C was on was only slightly cooler than outside temperature. The A/C was doing something - but not much. Borrowed a set of manifold gauges from the local Auto Plarts place and took a look on a few different days - most recently yesterday - and here's the situation:

Weather website said the outside temp was 77 degrees with 39% humidity. I start the car, let the A/C run for a while, then revved it to 2000 RPM for about a minute and let things settle back down. Ended up with a high-side pressure of about 160psi, low-side pressure just about 26psi, compressor running pretty steadily and not cycling fast like when initially running. Low-pressure side of the line running into the evaporator core through the firewall was cold, but not ice cold and return line coming out of the evap core much warmer. However, I stuck a thermometer in the vent and the air temp was only around 72 degrees - just barely below ambient.

I replaced the cabin air filters to make sure I was getting sufficient air flow over the evaporator core, but that had no real effect. I have a digital copy of the factory service manual and walked through much of the troubleshooting although it heavily leans on specifics of the automated testing tools they've got in the service centers. The acceptable pressures are given in this table, however, and this leads me to beleive that the compressor and controls are working as they should be:

So I guess my question is this: Where do I look next? I'm not an A/C expert and I'm desperately hoping it's not a bad evaporator core because I don't want to disassemble the whole car interior. It's pretty cheap and easy to replace the accumulator, orifice tube, and even condenser, but I don't want to just throw parts at it if there's some other troubleshooting I could do. Thanks in advance for any help.